- Print

- DarkLight

Introduction to SCOR: A common language

What is SCOR?

Supply Chain Operations Reference better known as SCOR is a management tool developed to evaluate performance of supply chains. It is an improvement methodology using process, indicators and best practices oriented towards customer satisfaction. So, communication and collaborations between stakeholders of the company is an important point.

It helps organizations to solve business problems and improve performances by identifying gaps and providing analysis needs in each level of the supply chain. The advantage of using SCOR is that it can be applied to any company regardless of the type of business, because it uses a common language.

SCOR Framework

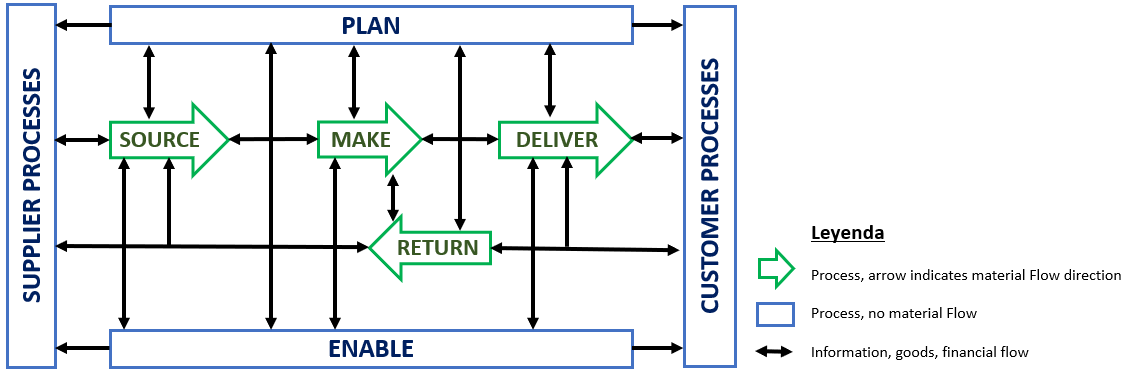

Through four main techniques SCOR attempts to achieve their goals. First, the processes must be examined, analyze current state and determine desired state, for benefit of continuous improvement.

Second, benchmarking similar measures to compare performance between different supply chains at all levels. Third, scores allow the chain to start below its competitors in order to improve performance through technological practices and solutions.

Finally, SCOR is committed to continuous learning and competence improvement focused on performance. It therefore links processes, metrics, practices and requirements on staff in one format.

Structure of the SCOR Model

As stated by (APICS, 2017), the purpose of the SCOR framework “is to define process architecture in a way that aligns with key business functions and goals. Architecture here references how processes interact and perform, how these processes are configured, and the requirements (skills) on staff operating the processes”.

It consists on the integration of four major sections (the 4P).

Processes

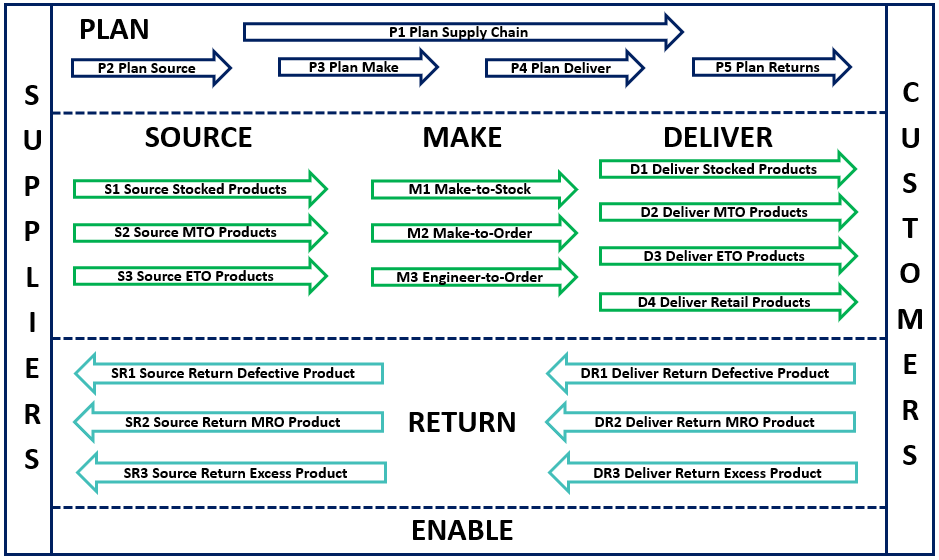

This section is divided into three levels. The first level provides a description for each process within the chain. SCOR has established the following types of process:

Plan

The balancing of requirements against resources

Provides two important functions:

- The mechanism for balancing demand requirements and available resources.

- An integrating funtion between other process elements and suppliers/customers.

Includes elements such as:

- Prioritizing demand requirements

- Planning inventory, distribution, production, material and rough-cut capacity for all products and all channels

- Supply chain configuration, long-term capacity and resource planning, business planning, product phase-in/phase-out, manufacturing ramp-up, end-of-life management, product-line management

- Manage planning infrastructure

Source

Activities that connect us to our suppliers

Document the activities that connect an organization to its suppliers.

Include activities such as:

- Material Acquisition

- Obtain, receive, inspect, hold and issue material

- Vendor certification and feedback, sourcing quality, in bound freight, vendor contracts, initiate vendor payments

- Raw Materials Warehouse management

- Raw Materials Transportation

- Manage traffic

- Manage inbound freight

- Manage Source business rules

- Manage RM inventories

Make

Change to form, fit or funtion

Make documents the processes that transform / converts raw materials into finished goods:

- Make processes do not imply a change of location but a qualitative transformation of the raw materials

- Not all organizations will necessarily perform Make processes

Make processes include activities such as:

- Request and receive material from Source processes

- Manufacture and test product, package, hold and/or release product

- Engineering changes, facilities and equipment, production status, production quality, shop scheduling / sequencing, short-term capacity

- WIP Transportation

- Manage production business rules

- Manage WIP inventories

Deliver

Activities that connect us to our customers

Deliver processes document the activities that connect an organization to its customers.

Deliver processes include activities such as:

Order management

Enter and maintain orders

- Generate quotations

- Create and maintain customer database, maintain product / price database

- Manage accounts receivable, credits, collections and invoicingFinished Goods Warehouse management

Store, pick, pack and configure products, create customer specific packaging / labeling, consolidate orders, ship products

Finished Goods Transportation and installation management

- Manage traffic, manage outbound freight, manage Schedule installation activities, perform installation, verify performance

Return

How to manage returns from your customers and to your suppliers

Return processes document the activities associated with the handling of returns, that is, the return of a product to a supplier or the receipt of a returned.

Return Source

- Activities associated with returning material to a supplier including the communication with the trading partner, the generation of documentation and the physical return / shipment of product.

Return Deliver

- Activities associated with receiving and disposing of returned material from a customer including the communication with the trading partner, the generation of documentation and the physical return / receipt and disposal of product.

Enable

It is related with the management of the supply chain.

📌 Each of the above process is associated with activities, which make up level 2 or also known configuration level. At level 3 or process element level, metrics and best practices are defined.

Level 3 is not covered in the next picture due to the length of its treatment.

Performance

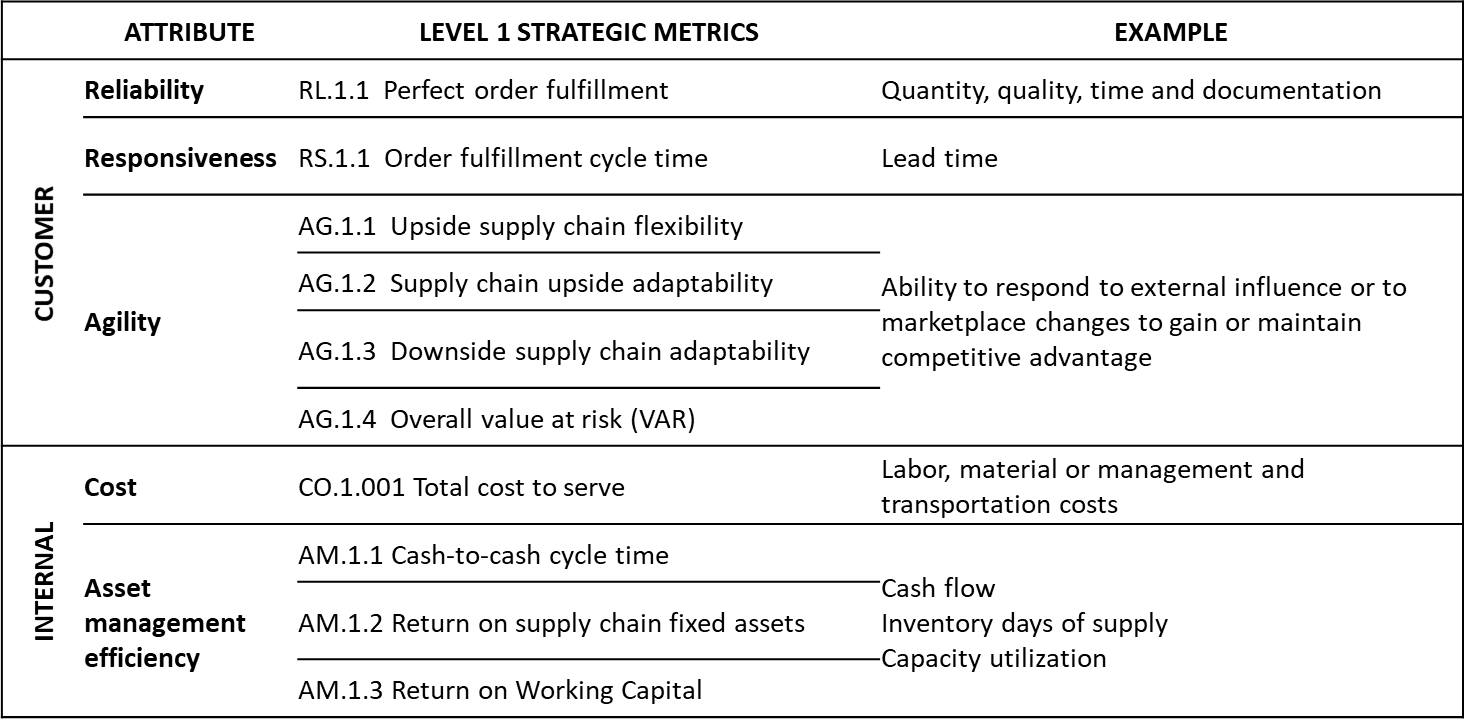

To measure process effectiveness, SCOR has established attributes and metrics divided into three levels, which are associated with each of the attributes. Through these two elements, companies can track each business and supply chain process. This will serve as a roadmap for continuous improvement.

Performance attribute

SCOR has defined five attributes that help express a specific strategy. Attributes are not measurable, but are used to establish the metrics.

- Reliability (RL) is defined as ability to perform tasks as required, for example receiving an order on time, with quality in quantity requested.

- Responsiveness (RS) is defined as speed at which tasks are performed, for example, time required to prepare an order.

- Agility (AG) is defined as organization's ability to respond correctly to changes due to external factors. For example, adapting to unexpected variations due to a natural disaster or the closure of a supplier.

- Cost (CO) refers to operating costs of the supply chain, such as labor, transportation, raw materials, etc.

- Asset management (AM) efficiency is defined as ability of the supply chain to efficiently use resources and assets, for example by reducing the inventory of raw materials or finished goods.

📌 Reliability, responsiveness and agility are customer-focused attributes. Cost and assets are internal-focused attributes

Metrics

Metrics are standards for measuring the performance of a supply chain or process. They are divided into three hierarchical levels and measure the ability of processes to achieve strategic objectives and are associated with attributes.

- Level 1 belong to a given performance attribute and this level is diagnostics for the overall health of the supply chain. These metrics are the key performance indicators or KPIs.

- Level 2 serve as diagnostics for the level 1 and helps to identify the root cause(s) of a performance gap for a level 1.

- Level 3 serve as diagnostics for level 2

Next is the detail of each attribute for level 1.

To see level 2 and 3 in detail click on the link.

Practices

Practices or best practices are a unique way of configuring processes. Their efficiency is proven and aims to significantly increase performance at every stage of the supply chain. They can be linked to one or several processes as well as metrics and are related to automation and technology.

SCOR recognizes the qualification of a practice may vary by industry or geography. For some industries a practice may be standard, whereas the same practice may be considered an emerging or best practice in another industry

Emergency practice

- Omni-channel

- Additive Manufacturing

- Block Chain

- Demand Driven MRP

- Demand Driven S&OP BP

- Digital Supply Chain

- Internet of Things

- Integrated Business Planning

- Scenario Planning

- SCM Object Synchronization – “3/4-way Mat

Best Practice

Supply Chain Risk Monitoring

Supply Chain Risk Assessment

Metadata

Cost of Quality

Data / Analytics

Supply Chain Finance

People

The people section defines standards for talent management in the supply chain by incorporating standards to describe the knowledge required to perform activities and manage processes.

A Skill in SCOR is the capacity to deliver results with minimal input of time and energy and experience is the knowledge or ability acquired by observation or active participation

SCOR recognizes five accepted competency levels:

- Novice: Untrained beginner, no experience, requires and follows detailed documentation

- Beginner: Performs the work, with limited situational perception.

- Competent: Understands the work and can determine priorities to reach goals.

- Proficient: Oversees all aspects of the work and can prioritize based on situational aspects.

- Expert: Intuitive understanding. Experts can apply experience patterns to new situations